EPP yog dav siv nyob rau hauv high-speed railway, tsheb thiab lwm yam khoom lag luam, xws li cov ntaub ntawv tseem ceeb, kev sib tsoo thaiv, lub ru tsev thiab lwm yam hauv ob sab phlu, qhov rooj filling, headrest, sunshade thiab lwm yam, uas yuav txuag tau roj noj thiab txhim kho. neeg nrog caij kev nyab xeeb yam.

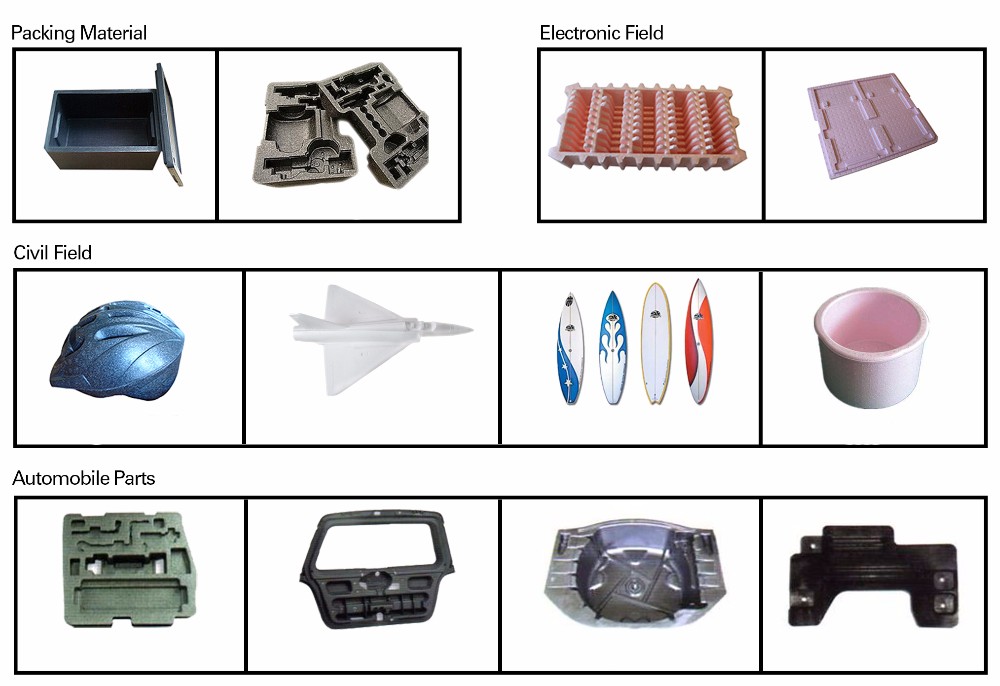

EPP tau siv dav hauv kev lag luam ntim khoom, xws li cov khoom siv hluav taws xob, cov khoom siv kho mob, thiab lwm yam, tshwj xeeb tshaj yog nyob rau hauv ntim cov khoom xa tawm, nws tau dhau los ua cov ntim khoom tsis tuaj yeem ua kom tau raws li cov kev cai ntawm kev tiv thaiv ib puag ncig.Vim nws tsis muaj tshuaj lom thiab kub tsis kam, nws kuj yog siv dav hauv ntim khoom noj thiab microwave cua sov.

Thaum kawg, EPP yog tsim los ntawm siab yaj lub zog polypropylene (HMSPP) es tsis zoo li polypropylene (PP).

General PP molecules yog dawb (tsis yog rab diav rawg) yuav tsum dhau los ntawm qee qhov kev ua haujlwm tom qab, kom nws cov molecules rau hauv rab rawg, feem ntau hu ua PP graft (kev graft degradation yuav tshwm sim, tsis txhob ua kom nws muaj viscosity siab thiab siab yaj lub hom phiaj. ).Feem ntau, EPP hlaws yuav tsum tau muab tso rau hauv lub tank siab ua ntej (txawm tias cov hlaws tau ntim nrog lub siab ntawm huab cua), thiab tom qab ntawd txhaj rau hauv pwm ntawm lub tshuab EPP molding tshuab nrog compressed cua los ntawm rab phom tsuag, los ntawm cov pa mus rau ntxiv nthuav cov EPP hlaws thiab nto fusion ua ke thiab tsim.Tom qab txias, cov pwm yog ruaj khov ntawm qhov kub thiab txias kom tau txais cov khoom EPP.

Post lub sij hawm: Jan-04-2022